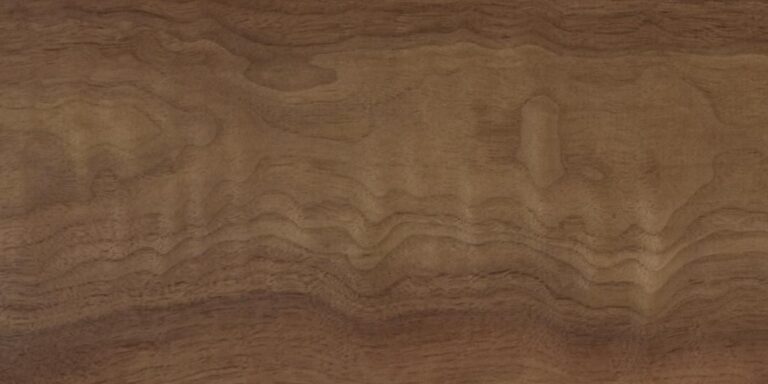

“Roasting” Soft Curly Maple involves gradually heating the wood up to temperatures of greater than 160 degrees celcius in special heat chambers made of stainless steel under anoxic conditions. The heat removes organic compounds from the wood cells, changing both the physical and chemical make-up of the wood. The process is natural and chemical free. It darkens the wood to a beautiful rich chocolatey brown color whilst still showing the gorgeous grain and figure of the underlying wood.

The thermally modified wood is more dimensionally stable, but the process does reduce bending strength and make the wood a little more brittle. This makes it chip a little easier than the un-modified lumber. The brittleness makes it less suitable for intricate cabinetry, but it is still an excellent choice for less intricate items such as floors, tops, panels, cladding etc.

Extra care needs to be taken when finishing thermally modified wood, as the "bone dry" wood has a tendency to "suck in" much of what is given to it. Our in-house woodworking specialist has had excellent results with Osmo PolyX. He suggests a thicker finish will work better.